Mechanical Engineering

A key capability that TA provides for government and industry customers is the ability to rapidly convert electro-mechanical and opto-mechanical concepts to solid models and shop-ready blueprints. This service leverages two of TA’s core competencies: 1) Expert-level familiarity with 3D CAD and modeling software tools including SolidWorks, AutoCAD, and Maya. 2) An understanding of mounting and assemblies, especially as pertains to product ruggedness and Mil-Spec testing requirements. All mechanical design, simulation, and fabrication at TA is overseen by David Thomas.

|

|

|

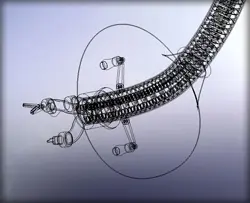

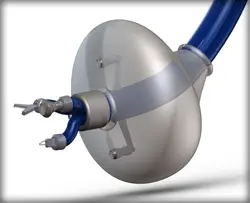

Figure: Medical manipulator device design : wireframe (left) and render (right) |

|

TA has delivered modeling products including stress, strain, load-induced deformation, and thermal conduction. As part of ongoing work in mobile robotic systems TA has excelled in modeling complex systems of moving parts such as gears and linkages. In role of developing drawings for custom fabrication TA has experience with modeling assemblies using metals, wood, plastics, CNC milling, injection molding, adhesives and ductile materials. In particular, TA has worked with steel casting houses to develop cast-to-drawing prints for medium scale (>100lbs) parts in a casting-CNC machining-finishing supply chain for military hardware.

In addition to modeling for fabrication, TA’s unique model visualization capabilities allows mechanical systems to be seen in relevant environments and to scale with supporting instrumentation and assets. TA’s expertise in visual rendering software such as SolidWorks, Maya and Houdini allows unique visual communication of the final application scenario of mechanical systems.